The Divergence Factor

When procuring construction services, the alignment between a contractor’s cost estimate and the independent cost estimate (ICE) is a critical benchmark. The Divergence Factor, the percentage difference between these two estimates, serves as an objective measure of alignment. Establishing the appropriate threshold for divergence at the outset of a project provides owners with a structured means of evaluating contractor proposals while simultaneously recognizing the inherent variability in cost estimating.

The Divergence Factor is calculated as the absolute difference between the contractor’s estimate and the ICE, expressed as a percentage of the ICE. This metric enables owners to assess the reliability of the contractor’s initial proposal. It serves both as a measure of estimating accuracy and as a mechanism for identifying potential risk of cost growth. A larger divergence generally reflects greater uncertainty or pricing volatility. A smaller divergence indicates closer alignment and reduced exposure.

Although a target range of 5% to 10% is commonly applied across the industry, the appropriate value is highly dependent on project-specific conditions. Owners should weigh several key considerations when establishing the threshold.

What are the key considerations to set the right divergence factor for your project?

Project Size - The implications of percentage-based thresholds scale with project magnitude. For example, a 10% divergence on a $10 million project permits a $1 million variance. The same percentage on a $100 million project permits a $10 million variance. While the ratio remains constant, the absolute dollar variance and the level of alignment required to achieve it differ significantly. Smaller projects may therefore necessitate tighter thresholds to preserve cost discipline.

Project Complexity - Complexity directly influences the predictability of cost outcomes. Projects involving specialized construction methods, constrained sites, or novel design features often exhibit greater variability in pricing between the contractor and the ICE. In such cases, owners may reasonably adopt a higher divergence factor to reflect these uncertainties. More routine projects may justify a more stringent standard.

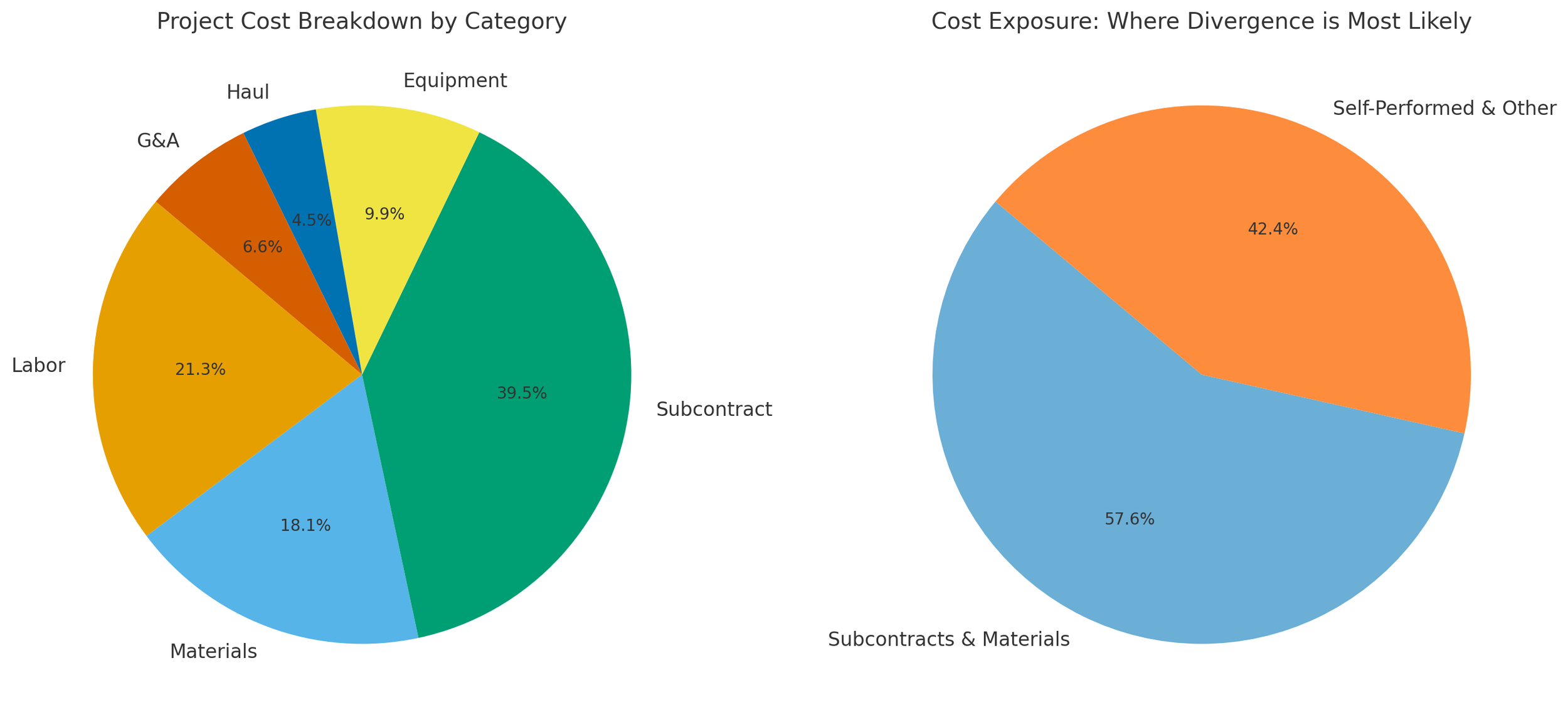

Self-Performed Work - The proportion of work self-performed by the contractor is often the most significant determinant. Subcontracted work and major material purchases are typically competitively bid, which means those costs are generally well-aligned between the contractor and the ICE. As a result, divergence is most likely to occur in the contractor’s self-performed labor and associated production assumptions. For example, if a contractor self-performs 50% of a $100 million project, a nominal 10% divergence factor allows for a $10 million variance against only $50 million of work. This effectively results in a 20% divergence on the self-performed portion. Owners should carefully consider this adjustment when establishing acceptable thresholds.

The Divergence Factor is a governance tool that balances accountability with the realities of cost estimating. Owners should establish thresholds based on the primary drivers of project size, complexity, and self-performed work, while also weighing supplemental considerations such as delivery method, design maturity, market conditions, project location, contractor experience, and contingency treatment. A well-calibrated threshold provides a balanced framework for managing variability, promotes transparency, reduces risk, and ensures contractor proposals remain aligned with independent assessments of fair and reasonable cost.

Susquehanna River Rail Bridge

The Susquehanna River Rail Bridge, carrying Amtrak’s Northeast Corridor across the river between Havre de Grace and Perryville, Maryland, is one of the most critical structures on the busiest passenger rail line in the country. Built in 1906, the bridge is a two-track swing span that has long exceeded its intended service life. Today it is the longest movable bridge on the NEC, requiring every train (Amtrak, MARC commuter, and Norfolk Southern freight alike) to slow to 90 mph as they cross.

More than 110 trains depend on this link daily, and the limitations of the aging bridge create a choke point that affects capacity, reliability, and on-time performance across the entire corridor.

To address this challenge, Amtrak has advanced a replacement program that will construct two new fixed bridges, each carrying two tracks. The design incorporates network tied-arch spans with steel girder approaches, offering a fixed vertical clearance of 60 feet and horizontal clearance of 235 feet to meet modern navigation needs on the Susquehanna River. By eliminating the movable swing span, the new structures will provide safer, more reliable operations for rail while also improving conditions for marine traffic.

Beyond the river crossing itself, the program includes modernization of nearly five route miles of railroad. This encompasses new approaches north and south of the river, upgraded interlockings, track realignment, and major improvements to the NEC’s signals and power systems. Together, these upgrades will allow higher passenger train speeds (up to 160 mph where alignment permits) and provide the long-term resilience needed for a corridor that supports millions of passengers each year.

The project is delivered under a Construction Manager at Risk model, pairing Flatiron/Herzog Joint Venture as CMAR with an AECOM-led project and construction management team. This approach brings the owner, builder, and oversight team together early in the process to address constructability, environmental requirements, and schedule coordination while keeping focus on safety and uninterrupted train service.

ICE Team’s Role

Innovative Contracting & Engineering (ICE Teams) serves Amtrak as the independent cost estimator for this nationally significant program. Our team develops and reviews comprehensive cost models that cover every discipline in the project (from civil and structural to track, systems, electrical, and mechanical). We verify quantities, evaluate labor and production assumptions, and account for indirect costs, escalation, and risk to ensure budgets are transparent and defensible. By providing a third-party perspective across the full scope, we help the owner maintain confidence that the investment is properly planned and financially sound.

Why It Matters

The Susquehanna River Bridge replacement is not just a construction project, it is a cornerstone of the Northeast Corridor’s future. By replacing a century-old chokepoint, the program will enhance safety, improve service reliability, and prepare the corridor for faster operations for decades to come. With disciplined delivery and independent cost validation, Amtrak ensures this generational investment secures one of the most vital rail corridors in the world.

Lexy Powers stands out as a dynamic and passionate program manager whose journey into construction was inspired by strong female mentors and a drive to make a tangible impact. Originally considering a career in law, Lexy was drawn to the construction industry by a family friend’s success and encouragement, ultimately earning her degree in construction management at Oklahoma State University. She quickly found her stride in a male dominated field, thriving on the camaraderie and the satisfaction of seeing projects come to life. Lexy’s early career in oil and gas construction provided her with foundational skills, but it is her work on impactful community projects, such as health centers and recreation facilities for tribal nations, that truly fuels her enthusiasm.

At ICE Teams, Lexy’s role as program manager is multifaceted and ever evolving. She acts as the central hub for communication and coordination, ensuring that projects run efficiently and that no detail falls through the cracks. Her ability to build relationships with tribal leaders and clients has been instrumental in expanding ICE Teams’ reach within tribal communities, and she takes pride in being a visible, reliable presence for clients and colleagues alike. Lexy is particularly excited about the company’s growing portfolio of alternative delivery projects and sees endless potential for innovation and partnership in the years ahead.

Lexy’s goals for the coming year include formalizing standards for program management at ICE Teams and contributing to the onboarding and development of future team members. She is also passionate about relationship building, both within the company and with external partners, recognizing that trust and reputation are key to success in the tribal construction space.

Outside the office, Lexy’s interests are as vibrant as her professional life. Lexy and her partner, Garrett, are avid home renovators and hope to flip several houses in the next year, channeling her love for hands on projects into new challenges outside of work. She also enjoys exercise, home renovation, and travel, having recently returned from a memorable trip to Spain. Whether she is walking her dogs, playing volleyball, or tackling a new DIY project, Lexy brings energy, creativity, and a sense of adventure to everything she does. Her advice to new employees is to immerse themselves in the field, build strong relationships, and always look for ways to add value. This wisdom has clearly guided her own impressive journey.

Alternative Delivery Consulting Services (PDB, CMGC, CMAR, DB, P3)

Alternative Delivery Processes Training

Independent Cost Estimating (Production-Based Cost Estimating)

Critical Path Scheduling Using Primavera P6

Constructability Reviews

Risk Management/Mitigation

Innovation in Construction Techniques

Negotiation

Change Order Reviews

We love what we do! We have a passion for finding creative approaches to construction. We are constantly looking for innovative construction techniques to add value to the projects we are working on. Our team has found ways to reduce schedule and/or construction costs on every project we have worked on to date!

Innovative Contracting & Engineering (ICE) is a team comprised of former contractors and professional engineers who have a thorough understanding of market fluctuations, pricing trends, construction strategies, and innovations. Our experience working on alternative delivery projects across the United States has provided our team with a tool bag full of industry best practices. Construction cost estimating and scheduling is our primary focus. This focus is how we stay current on construction trends and price changes, and that helps us produce more accurate estimates than our competition. We have a passion for finding creative approaches to construction. We are constantly looking for innovative construction techniques to add value to the projects we are working on. Our team has found a way to reduce schedule and/or construction costs on every project we have worked on to date! ICE works closely with our clients to improve the quality of their most challenging projects.

Past Newsletters:

Save Money with Smart Equipment Choices on Long Projects

How AI Can Help Make Construction Projects Run Smoother

Innovations are NOT “Negative Risks.”

CMGC or PD-B: Choosing the Right Delivery Method

Are Blue Book Equipment Rates Appropriate for use on Alternative Delivery Projects?

Free Tools! - Innovations Tracking

Pareto’s Principle and Concept Cost Estimates

Meeting Project Risks & Challenges

Leaders Turn Vision into Infrastructure

Early completion milestone bonuses in CMGC contracts

Risk Management Best Practices

Vision 2020?? Nobody saw this coming!

How can we help you? Send us your questions, comments, and request.

Email, Call, or Text: Dan Bender, 702-523-2354, danbender@iceteams.com