NO MORE! Death by a Thousand Cuts: Managing Redundancy in Estimates

On alternative-delivery projects, it’s not uncommon for Guaranteed Maximum Price (GMP) submittals to appear reasonable when reviewed line-by-line yet become surprisingly high when viewed in total. One of the biggest reasons is that some contractors load their estimates with large numbers of redundant or overlapping bid items, child items, and activities. Each individual line may look harmless, but collectively these small adds quietly drive global pricing beyond what is truly reasonable. At ICE Teams, we refer to this trend as “death by a thousand cuts.”

Accuracy = Trust. Cost growth can also be buried in places most owners don’t immediately review. We routinely see additional dollars embedded in direct labor build-ups, staff rates, indirect labor markups, and even in equipment rates. Individually, many of these cost factors may seem justifiable; however, without clear mutual structure and agreed-upon rate conventions at the outset, these additions accumulate into significant cost exposure. A major lesson learned is that the structure of bid items should never be left open-ended. As an Independent Cost Estimator, we now make it a standard practice to jointly develop the bid and child item framework with the contractor before estimating begins, so we eliminate duplication and scope inflation through excessive activity segmentation.

Equally important, we aim to pre-establish direct and indirect labor rates, equipment rates, and typical “plug” pricing for subcontractor and material unit costs. When the underlying economics are agreed to early, the focus of negotiation shifts to true project scope and productivity assumptions, not hidden markups or embedded multipliers. This upfront alignment becomes especially critical on complex, phased, or fast-track alternative delivery projects where transparency and speed matter.

Finally, one of the most powerful tools we use is key global metrics to quickly test the reasonableness of the estimate as a whole, rather than just reviewing details item by item. We look at cost per linear foot, cost per cubic yard, cost per bridge span, labor productivity metrics, self-performed ratios, staff loading factors, equipment utilization, and a wide set of unit-level and global benchmarks. These metrics help us sort and filter issues quickly, flag anomalies, and identify where the estimates are diverging from industry norms or previous milestones. Instead of debating hundreds of line items, we can pinpoint real problem areas in minutes and focus discussions where they matter.

Our processes and systems have become essential in protecting owners from excessive GMP pricing and ensuring transparency throughout every stage of negotiation. By aligning on structure, rates, and benchmarks upfront, we eliminate hidden markups and duplication, keeping the focus where it belongs: on scope, productivity, and value. These disciplined practices don’t just safeguard budgets; they build trust, accelerate decision-making, and deliver projects with clarity and confidence. It’s how we turn complexity into certainty and ensure every dollar works harder for our clients and taxpayers

Building Resiliency: The P7 Ridgeway Water Treatment Plant Project

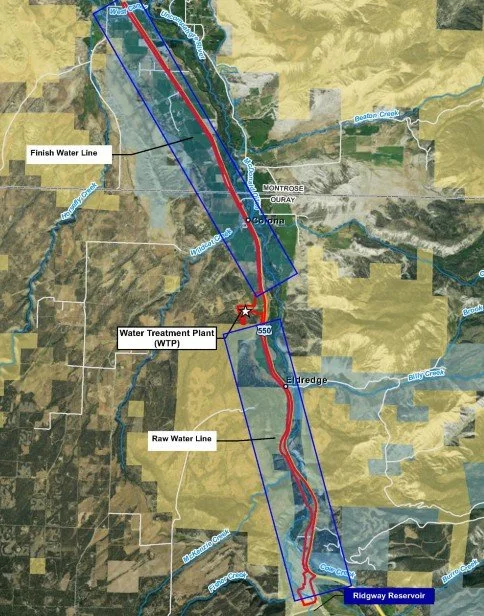

The P7 Ridgeway Water Treatment Plant Resiliency Project represents a forward-thinking investment by Project 7 Water Authority to strengthen long-term water reliability for western Colorado. Delivered using a Progressive Design-Build (PDB) approach, the project highlights both the opportunities and challenges that come with delivering complex water infrastructure in today’s market.

The project scope included the development of a new water treatment facility downstream of the Ridgway Reservoir, along with a critical transmission pipeline connection to Project 7’s existing system. The facility incorporates multiple specialized treatment processes, including pellet softening, ultrafiltration membranes, CO₂ systems, fluorine gas scrubbing, and supporting infrastructure such as energy recovery components and on-site weigh scales.

Beyond the plant itself, the project encompassed approximately 5.25 miles of underground piping, extensive rock excavation, and construction activities within constrained corridors and DOT-regulated rights-of-way. Together, these elements created a technically complex project with significant cost, schedule, and risk considerations.

By selecting a Progressive Design-Build delivery model, Project 7 emphasized early collaboration, transparency, and iterative decision-making. This approach allowed the owner and project team to advance design while continuously evaluating cost, risk, and constructability as the project evolved.

ICE Teams was engaged by Garver to provide independent preconstruction support, including production-based cost estimating, construction scheduling, risk register development, constructability reviews, and estimate reconciliation at key design milestones. This independent perspective helped inform decision-making as scope, risk allocation, and market conditions became clearer through the design process.

Alternative Delivery Insights

The P7 Ridgeway project underscores the importance of early cost transparency, independent validation, and clear alignment between owner expectations and delivery model realities, particularly for highly specialized water and wastewater facilities. Progressive delivery methods can offer tremendous value, but they also require disciplined cost controls and continuous owner engagement as design and risk are refined.

ICE Teams is proud to have supported Project 7 and Garver by providing objective, contractor-informed analysis to help guide these critical decisions. Even when projects evolve or change course, independent cost estimating plays a vital role in ensuring owners have the information needed to make confident, informed choices.

Why It Matters

Water infrastructure projects are becoming more complex, more specialized, and more sensitive to market conditions. The P7 Ridgeway project demonstrates how independent cost estimating and risk analysis support owners in navigating these challenges, ensuring that decisions are grounded in data, transparency, and long-term value.

We're delighted to feature Chad Harless, one of our skilled cost estimators, in this quarter's newsletter! Chad brings diverse experience to our team, starting with a background as the son of a piano teacher. He began teaching piano himself at just 11, an experience that cultivated early skills in time management, communication, and self-direction, qualities that serve him well today. Chad's path led him through various states and careers, ultimately landing him back in construction after earning a degree in Construction Management from BYU Idaho. His construction experience, which included an internship with a specialty contractor insulating industrial systems, was briefly interrupted by a rewarding stint in law enforcement in rural Idaho, where he enjoyed the unique role of a "cowboy cop" helping people in the remote wilderness.

Chad's return to construction and eventual arrival at ICE was directly influenced by his respect for our Senior Estimator, Jon Farrar, and the positive reputation of our leadership, including Kyle Norseth, both of whom have previous history at Ames Construction. Currently, as a Cost Estimator at ICE, Chad's role involves roughly half his time dedicated to quantity takeoffs, and the other half focused on estimating. Furthermore, he's actively stepping into an Assistant Project Lead role, contributing significantly to cost comparison sheets and background work for OPCC meetings.

Looking ahead, Chad’s goal for the upcoming year is to transition into a full Project Lead role within the next year, building on his current responsibilities. To further enhance his expertise, Chad plans to dive deep into ICE's comprehensive nationwide project data, viewing it as an invaluable resource to quickly gain insight into industry cost norms that typically take decades of experience to acquire. Beyond work, Chad is an avid enthusiast of classical literature and is focused on finding more time to read physical books, though he currently enjoys listening to audiobooks while working.

Outside of estimating and reading, Chad focuses his energy on one of his biggest passions: endurance sports. He and CJ Barker recently completed an insane 17.1-mile mountain race, which involved running and hiking up a steep slope at high altitude. This drive is reflected in his professional mindset—Chad believes in being a team player who doesn't say no to a demanding workload, embracing the philosophy that "iron sharpens iron." On the personal front, Chad and his wife, Lauren, are expecting their first baby soon. They are also close to finishing construction on their new home, where they look forward to raising their family and eventually keeping horses.

Alternative Delivery Consulting Services (PDB, CMGC, CMAR, DB, P3)

Alternative Delivery Processes Training

Independent Cost Estimating (Production-Based Cost Estimating)

Critical Path Scheduling Using Primavera P6

Constructability Reviews

Risk Management/Mitigation

Innovation in Construction Techniques

Negotiation

Change Order Reviews

We love what we do! We have a passion for finding creative approaches to construction. We are constantly looking for innovative construction techniques to add value to the projects we are working on. Our team has found ways to reduce schedule and/or construction costs on every project we have worked on to date!

Innovative Contracting & Engineering (ICE) is a team comprised of former contractors and professional engineers who have a thorough understanding of market fluctuations, pricing trends, construction strategies, and innovations. Our experience working on alternative delivery projects across the United States has provided our team with a tool bag full of industry best practices. Construction cost estimating and scheduling is our primary focus. This focus is how we stay current on construction trends and price changes, and that helps us produce more accurate estimates than our competition. We have a passion for finding creative approaches to construction. We are constantly looking for innovative construction techniques to add value to the projects we are working on. Our team has found a way to reduce schedule and/or construction costs on every project we have worked on to date! ICE works closely with our clients to improve the quality of their most challenging projects.

Past Newsletters:

Save Money with Smart Equipment Choices on Long Projects

How AI Can Help Make Construction Projects Run Smoother

Innovations are NOT “Negative Risks.”

CMGC or PD-B: Choosing the Right Delivery Method

Are Blue Book Equipment Rates Appropriate for use on Alternative Delivery Projects?

Free Tools! - Innovations Tracking

Pareto’s Principle and Concept Cost Estimates

Meeting Project Risks & Challenges

Leaders Turn Vision into Infrastructure

Early completion milestone bonuses in CMGC contracts

Risk Management Best Practices

Vision 2020?? Nobody saw this coming!

How can we help you? Send us your questions, comments, and request.

Email, Call, or Text: Dan Bender, 702-523-2354, danbender@iceteams.com